IN THIS ARTICLE

Table of Contents

Backlogs and inefficiencies occur when you lack human resources (HR) to speed up your daily production. Increased costs emerge when you hire new employees and buy equipment to fill such gaps. System maintenance and upgrades also add to your expenditures.

Business process outsourcing (BPO) can be a game-changer in this situation. The approach offers cost-effective solutions to boost your productivity. Service providers employ skilled professionals to improve efficiency without overspending.

Stay on this page to understand how streamlining operations in manufacturing through BPO helps expand your enterprise.

Streamlining Operations in Manufacturing Through BPO

Cost efficiency is vital to thriving in the fast-paced manufacturing industry. But what is BPO, and what is its role in achieving that?

Outsourcing serves as manufacturers’ gateway to expedite their business operations. Partnering with service providers lets manufacturers optimize various aspects of their processes to ensure remarkable improvements at affordable costs.

Let us explore how BPO is crucial to streamlining operations.

Reduce Operating Expenses

One big reason why manufacturers adopt outsourcing is to save money while expanding their capabilities. A recent Deloitte survey recorded that 88% of executives found reducing costs an important benefit of outsourcing.

When you assign repetitive tasks to a BPO provider, you can say goodbye to recruitment, training, compensation, equipment, and office space expenses. Instead, you only need to pay fixed monthly or hourly fees for the following outsourced manufacturing-related services:

- Designing, development, and assembly

- Order processing and fulfillment

- Logistics and transportation

- Inventory management

- Procurement and supply chain administration

- Quality assurance and testing support

- Data entry and analysis

- Customer service and technical assistance

- Finance and accounting support

- Manufacturing system maintenance and management

- Compliance and regulatory services

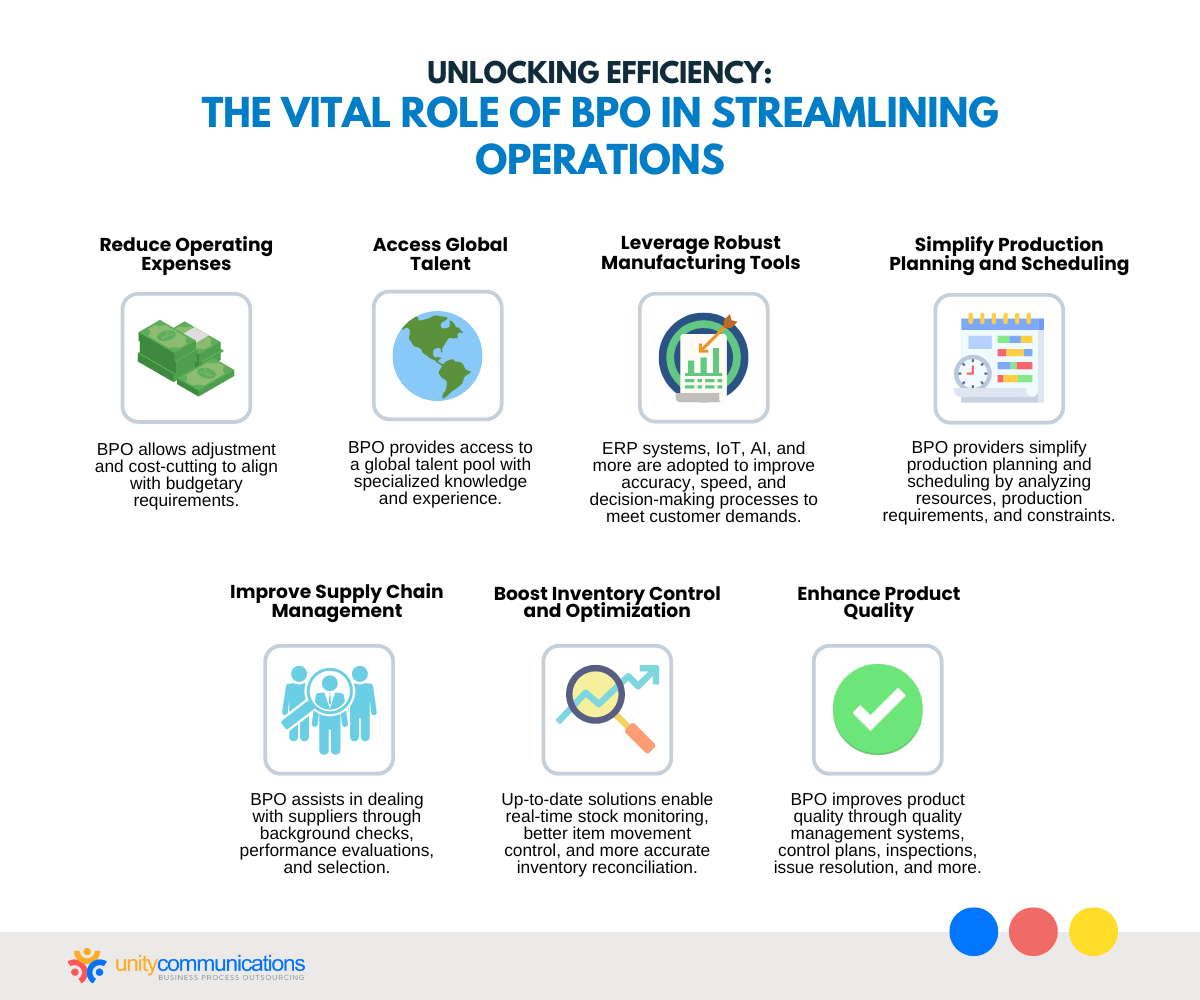

Additionally, BPO lets you adjust and cut costs to align with your budgetary requirements. It gives you greater control over your financial resources.

Access Global Talent

Streamlining your operations in manufacturing through BPO gives you access to a global talent pool. Service providers employ well-trained professionals with specialized knowledge and experience to support your business processes.

Below are the skills and capabilities that make BPO professionals valuable partners for your manufacturing business:

- Understanding of different manufacturing processes and best practices

- Familiarity with industry-specific workflow and regulatory requirements

- Ability to implement quality control measures and safety standards

- Proficiency in using manufacturing hardware and software tools

- Expertise in technical areas such as engineering and production planning

- Ability to effectively collect, analyze, and extract manufacturing-related insights

- Ability to determine problems and areas for improvement

- Capacity to coordinate and accomplish multiple tasks before their due dates

- Focus on maintaining and enhancing product quality

- Oral and written communication for smooth collaboration

- Adaptability and flexibility to changing work conditions and industry shifts

- Propensity toward prioritizing superior customer experience and customer satisfaction

Leverage Robust Manufacturing Tools

Numerous BPO roles and responsibilities involve leveraging robust manufacturing technologies to increase efficiency. The enumerated tools below help improve accuracy, speed, and decision-making processes to satisfy customer demands:

- Artificial intelligence (AI) and machine learning (ML)

- Enterprise resource planning (ERP) systems

- Internet of things (IoT) technologies

- Robotic process automation (RPA)

- Advanced analytics and data visualization

- Cloud computing solutions

- 3D printing technology

- Virtual and augmented reality (VR/AR) training tools

- Supply chain management systems

- Cybersecurity solutions

Simplify Production Planning and Scheduling

BPO providers bring extensive experience and unmatched expertise to simplify production planning and scheduling. Providers ensure optimal resource utilization and reduce insufficiencies with advanced technologies and skilled talent.

Service vendors analyze resources, production requirements, and constraints to accomplish these goals. They consider labor capacity, machine availability, material availability, and lead times to develop feasible production schedules. This action helps avoid bottlenecks, minimize idle time, and maximize throughput.

Improve Supply Chain Management

Enhanced supply chain management is critical when streamlining manufacturing operations through BPO. Third-party contractors assist in dealing with suppliers by performing background checks, performance evaluations, and selection.

Service vendors use data analytics technology to provide real-time visibility into the supply chain. These visibility tools help monitor and assess supply chain performance based on key performance indicators (KPIs). The resulting insights inform your decisions for business development and issue resolution to help meet customer expectations.

Due to such convenience, the supply chain management BPO market was expected to reach almost $29 billion in revenue in 2023. According to Future Market Insights, the sector will expand at a compound annual growth rate (CAGR) of nearly 9.7% to approximately $73.34 billion by 2033.

Boost Inventory Control and Optimization

Manufacturing BPO companies apply proven techniques such as economic order quantity analysis (EOQ) to boost inventory control and optimization. Moreover, they use modernized systems to improve inventory management and tracking.

Deploying up-to-date solutions such as barcode systems and radio frequency identification (RFID) technologies helps ensure inventory accuracy and visibility. This capability enables real-time stock monitoring, better item movement control, and more accurate inventory reconciliation.

Enhance Product Quality

Expect improved product quality when streamlining operations in manufacturing through BPO. Delivering high-quality products builds customer loyalty, strengthens brand reputation, and increases your bottom line in the long term.

A BPO organization understands those benefits. Hence, providers use the following methods to help enhance your primary products and services:

- Help maintain quality management systems for manufacturing operations.

- Draft quality control plans and techniques.

- Implement effective quality control measures throughout the production process.

- Conduct inspections and product tests to ensure compliance with quality standards.

- Identify and resolve quality issues beforehand to minimize defects.

- Establish and execute supplier quality management strategies.

- Train employees on quality control and product inspection methods.

- Collect and analyze manufacturing-related data for continuous improvement.

Learning from Actual Manufacturing BPO Clients

Studying previous clients’ experiences brings valuable insights into manufacturing BPO advantages. These stories show how organizations successfully use outsourcing to overcome challenges, optimize resources, and gain significant benefits.

Below is a list of companies that have embraced manufacturing BPO:

- The Coca-Cola Company has outsourced to cut manufacturing, bottling, and storage costs. BPO helped the beverage company set up local manufacturing and distribution networks, lowering such expenses due to competition. This partnership lets The Coca-Cola Company focus on boosting its syrup production, which has become its primary source of revenue.

- Samsung Electronics streamlines its manufacturing operations through BPO to attain cost competitiveness. The South Korean conglomerate started large-scale outsourcing in 2019 to launch a full lineup of smartphones at a lower price. The company wants its smartphone pricing to match worldwide markets.

- Amazon works with a service provider to address duplicates in inventory. Entrusting the multinational e-commerce company’s inventory management to third parties decreases labor funding and accelerates product delivery.

- Apple has collaborated with Chinese manufacturers to cut its production costs. In fact, 50% of Apple’s 200 top suppliers operate in Shanghai. Also, BPO allows the tech giant to prioritize its design process while an overseas provider handles its manufacturing.

- Nike has gained significant cost reduction, better revenue, and enhanced competitiveness by outsourcing its footwear production to China, Vietnam, the Philippines, Indonesia, and Taiwan. Half a million workers worldwide support Nike’s manufacturing and quality control.

Ensuring Successful Manufacturing BPO Implementation

Picking the right service vendor is the first step in ensuring success when hiring manufacturing BPO services. Of course, you must perform market research and background checks before signing an official contract.

At the same time, you should know what you want to gain from partnering with a provider. Identifying challenges to resolve and improving areas helps develop a well-structured BPO plan.

Note that outsourcing is still a form of investment. So you must be careful when planning your move to avoid wasting money, time, and effort. Once you seal a deal, ensure aligned goals, compatible work strategies, and centralized communication channels to attain superior outcomes in the long run.

The Bottom Line

You experience persistent inefficiencies and delays when assigning all your production processes to your in-house teams. If left unresolved, this work can overshadow your labor force and resources, compromising product quality.

Acquiring a manufacturing BPO helps address such gaps. Providers offer cost-effective services to improve your production, product quality, and inventory management. Their skilled employees and advanced tools enable them to deliver affordable support.

Do you want to streamline your operations in manufacturing through BPO? Let’s connect and negotiate an agreement. Unity Communications has an award-winning team of highly skilled employees and robust technologies to meet your daily production needs.